C10 Rear Frame Rail Kit 1967-72

With the popularity of ’67-’72 GM trucks reaching an all time high, the question that many of you may be asking is how do I find a short bed that is in good shape? When they were first produced the need for a truck was to work out of or carry a camper in the bed, so most of the models made were long bed versions while the short bed numbers were few and far between. This has made short bed models worth more later on based by their limited production, and the desire to use them as daily transportation. However because of the low production runs, finding an affordable short bed model in good shape seems to be going the way of the dodo bird.

So what about converting a long bed to a short bed? There’s plenty to choose from and most of the long bed models were better equipped from the factory. But where can you find the sheet metal for the short bed and what about the frame? The good news is reproduction sheet metal is available from Classic Industries for these models, as well as a bolt on, back half frame kit from No Limit Engineering. The best part about using this combo is the difference in initial cost to purchase a rust free long bed, covert the frame to a short bed, and buy the reproduction sheet metal can save you some money and or end up with a cleaner truck in the long run if you were to look for a clean factory short bed.

Now this conversion might seem like a lot of hard work that involves heavy fabrication tools and or skills that many might not have. On the contrary my friend, as a matter of fact if you think that you can install a frame “C-notch”, then you can tackle this conversion in just a weekend’s time! Plus one of the advantages of using this combo is No Limits’ “step up rails” that allows you to lower the rear of the truck 4-inches while maintaining the factory ride. Plus, the advantages of using Classic Industries sheet metal is no rust repair which means less body work that will save you so major time and a ton of money.

Think you’re ready to tackle it and drive away with a short bed C-10? Take a look at how we did it in the better part of two days on this ’71 long, I mean, short bed truck.

We pulled this ’71 long bed C-10 out of a guy’s back yard for $500 bucks. It was in great shape and even had a good 454 engine in it.

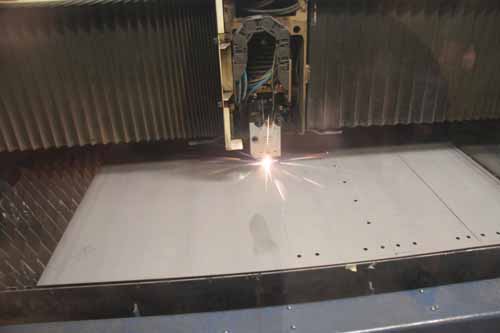

The first stop on quest was to shorten the rails of the long bed truck, so a visit to No Limit’s production room is where we found Rob already cutting out a frame rail from a sheet of steel on the Laser table. The precision cuts that this type of equipment makes is fascinating yet confusing as Rob swore to us that this piece really becomes a frame rail.

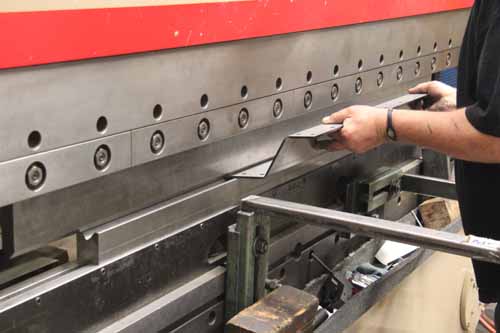

To clear up the confusion Rob directed us over to where Bill was setting up the press brake. Here in the photos we can see an example of him bending out one of the cross-members that laterally holds the main rails together.

Now you can compare an example of the piece that Rob cut using the laser table, to another rail that was cut and bend into a frame rail using the press brake. After all the pieces were cut and bent they’re placed on a pallet, just like how No Limit ships them out to their customers. You too can get your hands on the same kit shipped right to your front door with a click of a mouse.

To make it easier to show you the work in photos, we stripped the truck down to it’s chassis but this is not required to do so for this conversion. A few guys and the better part of the weekend will get the job done just fine.

We moved the chassis over to the assembly room and figured that the easiest way to remove the rear suspension was to drop the shocks, Panhard bar and the top spring plates that attach the springs to the frame. Next we unbolted the two bolts that hold the trailing arms in place to the trailing arm cross-member and rolled out the whole thing in one piece.

Next we double checked to see that the chassis was level, and began to measure out where to cut the frame just past the rear cab mount.

Measuring twice to cut once, we ran the reciprocating saw blade down the mark on both sides until the frame was in two pieces!

In this photo you can see the difference between the stock long bed frame section on the left to the new frame section from No Limit on the right. Don’t let the photos fool you, although they still might look similar there are a slew of changes that affects the new short bed section making it possible to install the short bed sheet metal and get it low to the ground while maintaining a great ride and proper handling.

We found that the simple way to install the rails was to locate the factory holes on the top and bottom of the stock frame just past the cab mount. Then slide on one frame rail at a time and bolt them together. Next mark, clamp, and drill out the rest on the mounting holes that are indexed on the No Limit frame rail through the stock frame. Run in the fasteners in to ensure that you get in tight fit then remove the rails to install the cross-members off the truck.

The No Limit C-10 back half is a bolt on system that comes shipped on a pallet, so just like your first big wheel when you were a kid the “some assembly required” statement is true. With the rails off the truck slide each cross member in place on bolt them up. Now find some help, (kids ask your parents) and lift / align it onto the stock frame rails.

After bolting the new rails to the stock rails, we installed the rear differential back in place to the trailing arm cross-member and we had a rolling short bed chassis!

Just like No Limit’s C-10 back half kit can be shipped to your door, the same goes for the sheet-metal that was shipped from Classic Industries. Here Tylor starts to assemble the bed by laying out the bed floor and taking some measures to get both pieces of the floor as square as possible before bolting on the bedsides.

With the bedsides in place, Tylor moves on to mounting the front bulkhead by using a screw-driver to help align the pre drilled bolt holes that mount the front panel to the bed floor.

Some of the pre- drilled holes may be a bit off, so don’t be afraid to “slot” them out using a porting bit and a drill motor.

Classic Industries makes things easy to ship, and or repair stock bed floors by manufacturing the steel bed floor in two pieces. At the center of the bed both panels overlap forming a seam. We chose to weld it together using Miller electrics model 211 MIG machine. Be sure to always wear your safety equipment to ensure safe operation when welding anything. After we prepped the seam to accept the wire, we tacked the seam together first followed by a pass over the tacks to ensure a strong seam.

Before we set the cab and the front end back on the truck, we installed a new set of Energy suspension frame mount bushings. These bushings not only out live the factory style rubber mounts at least 2 to 1, but also assist your trucks suspension by reducing the amount a sway that the OEM style rubber mounts can’t take. It’s kinda like what “Tommy John’s surgery” does for a Major League Baseball pitchers elbow.

Now it was time to lower the bed onto the frame mounts and align the bed to the cab.

In this photo we removed the bed floor to show you how the cross members and wheel tubs fit in place. Since the No Limit C-10 back half kit changes the geometry of the frame rails up by 4-inches, the stock bed floor will need to be raised up or a section will need to be cut out so that the bed will fit back into place. Stay tuned as we show you how to do that and set up the suspension in an up and coming issue.